From our custom hulls, boat rubrail, to custom DEF tanks and custom barges, we use HDPE to make lightweight and durable custom marine products. With its unique properties, HDPE is a super buoyant yet strong material that, as a hull, is not afraid of sharp rocks close to shore and is known for its ability to resist marine growth and cracks. You can hit it with a sledgehammer!

HDPE, or High-Density Polyethylene, is quickly becoming the material of choice for many custom marine products. HDPE has a much lower carbon footprint than aluminum, making it an environmentally friendly choice. HDPE can last for many years with minimal maintenance, making HDPE an excellent choice for those looking for a long-term investment.

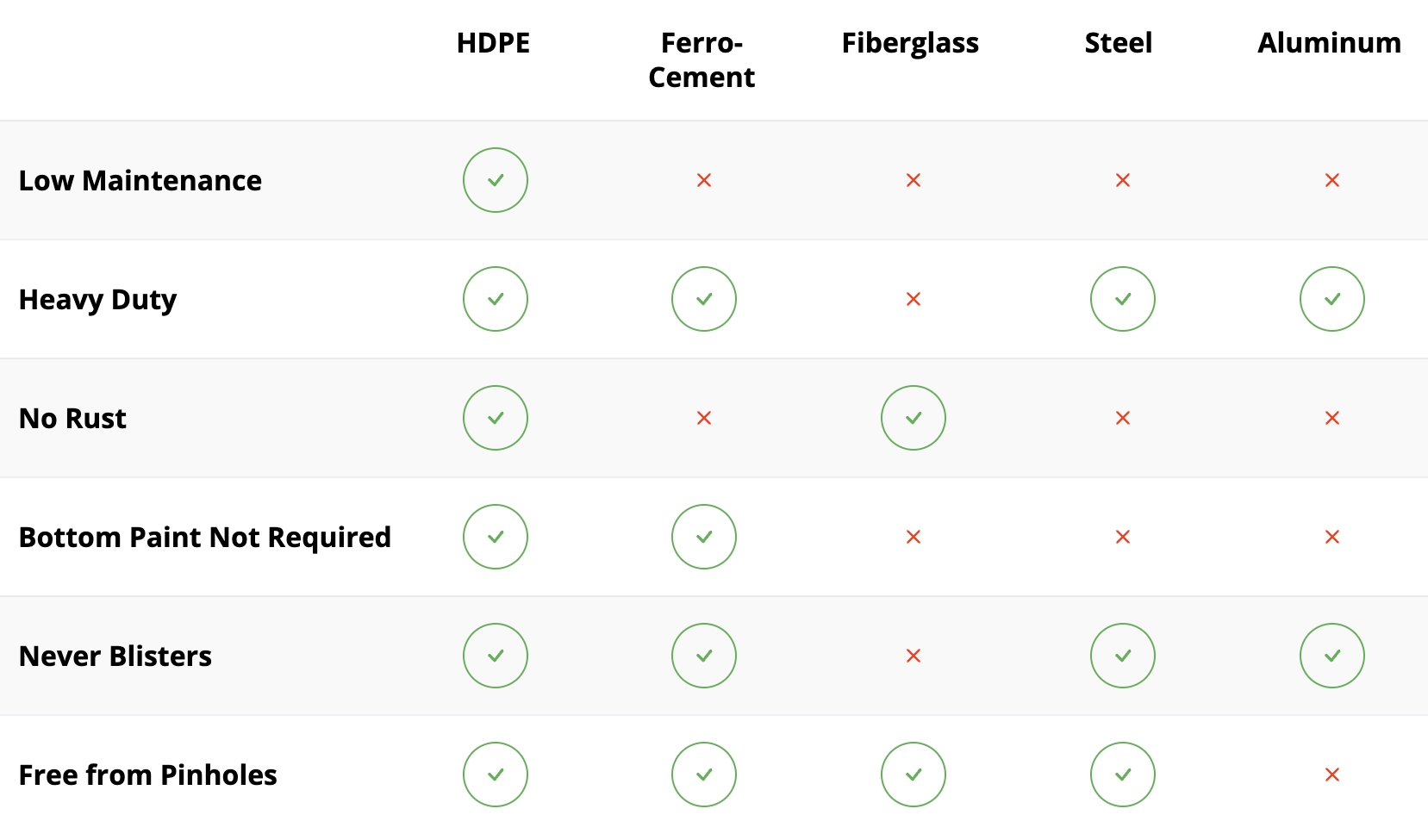

HDPE is resistant to UV rays, saltwater, and corrosion. It does not require painting or rinsing, making it a low maintenance and easy to clean marine material. Additionally, HDPE does not require antifouling coating. HDPE is also an outstanding choice for custom marine products because it’s highly resistant to damage from aggressive liquids.

In the rare event your HDPE custom marine product is damaged and in need of repair, you can either bring your hull to a plastic fabrication company or inquire about a welding kit to do the repairs yourself.

Fun fact. HDPE is unique in that it can be 100% remelted and recycled into a new PE blend. Unlike fiberglass construction (GRP) HDPE can be recycled to create new products, reducing the impact to the environment. Aluminum boats are solid and more durable than fiberglass boats, however, metal deterioration will eventually degrade the functionality and serviceability. In addition, HDPE’s production process has a much lower carbon footprint than other materials, such as aluminum, making it an attractive option for those looking to reduce their environmental impact.

HDPE has many positive attributes that make it a perfect material for the marine industry. HDPE is durable, lightweight, can withstand the elements, is buoyant, low maintenance, recyclable, and UV resistant. With all these benefits, it’s no wonder that HDPE is quickly becoming a material of choice for boat hulls and many custom marine products.

"*" indicates required fields

For marine product manufacturers looking to replace or expand their material options, HDPE is an ideal choice. HDPE offers a range of benefits that make it an attractive alternative to aluminum, fiberglass, and steel – lightweight, durable, and corrosion-resistant. HDPE flexible fabrication process also allows for a wide range of designs. With its superior strength-to-weight ratio, HDPE is an excellent choice for marine products that need to be lightweight, yet strong. Converting your designs to HDPE can offer your customers a reliable and cost-effective material option.